The pvc pipe production line is developed with 1990s advanced technology of Europe by our company. The main machine is conical twin screw extruder with three models to options. Equipped with dual pipe single-control vacuum calibration tank, it avoids a waste condition if one pipe is adjusted and the other is affected. The auto single-control double puller and cutting are combined with the front shaping technology to mak operation more flexible. Let you economic benefit which is brought about by separately control dual pipe extruding. The diameter of the extruded pipe is from 16mm to 63mm. it can make fully use of the extruding capacity of extruder. Even if it produces small diameter pipe, it can get great output too.

The production line is a double pipe extrusion equipment with high output. The main machine is sjsz51 / 105 or sjsz65 / 132 conical twin-screw extruder, which is equipped with a two pipe control device. The stainless steel spray forming forms a complete production line, which can avoid the situation that one pipe has been adjusted and the other pipe has been affected. The good combination of automatic one-way control and double traction cutting machine can make the equipment operate more flexibly by using the front-end technology design, and the double pipe extrusion can be used The single control technology enables you to enjoy the excellent economic benefits. The diameter range of extruded pipe is φ 20 - φ 63 (mm), which can meet the output of extruder very well. Even the pipe with smaller diameter can achieve a larger output.

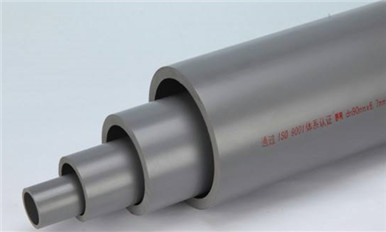

CPVC pipe, as a new type of pipeline, has excellent corrosion resistance. In recent years, CPVC pipe is widely used in steel, metallurgy, petroleum, chemical industry, fertilizer, dye, pharmaceutical, electric power, environmental protection and sewage treatment industries, and it is an ideal alternative to metal anti-corrosion materials.

Due to the increase of chlorine content in the material, the irregularity of CPVC molecules increases in structure (the crystallinity decreases, the polarity of molecular chain increases), so the thermal deformation temperature of CPVC increases. A kind of

The use temperature of CPVC products can reach 93-100 ℃, which is 30-40 ℃ higher than that of PVC. At the same time, it improves the chemical resistance and corrosion resistance of PVC, and can resist chemical corrosion of strong acid, strong alkali, salt, fatty acid salt, oxidant and halogen. A kind of

In addition, the tensile strength and bending strength of CPVC are also improved compared with PVC. Compared with other polymer materials, CPVC has excellent aging resistance, corrosion resistance and high flame resistance. The chlorine content of CPVC raw material is 63-74%, which is higher than that of PVC (chlorine content is 56-59%). The processing viscosity is at least twice as high, and the density of CPVC (between 1450-1650kg / M) is larger than PVC. The above data determines that CPVC is much more difficult to process than PVC.

Wooden pallet, PE film package.

Name: Bruce Lee

Mobile:+86 13401660891

Tel:+86 13401660891

Whatsapp:008613401660891

Email:laishide@foxmail.com

Add: No.48, Ma Xuan Village, Huangli Town, Wujin District, Changzhou City, Jiangsu Province, China